Our story

A short story of ups and downs.

And a few emergency stops.

“I’d like a computer controlled lift, shouldn’t be a problem, right?”

As a newly minted computer technology engineer back in 1983, Bengt Wirgart was surprisingly intrigued by the task at hand. Bengt had been sent to the requesting older gentleman by a friend that ran a lift service company. “A computer controlled lift, interesting”, Bengt thought to himself. Bengt himself didn’t work at the lift company, he was a service technician for a company that sold the home computer of the day – the Commodore Vic 20.

Bengt Wirgart [Founder]

01

Bengt swiftly learned machine code and wrote a program to computer-control the lift. It worked beautifully.

The innovator finds his calling.

In 1983, computer-controlled lift systems was basically unheard of. The lift industry was lagging far behind most business with regards to computer technology. Bengt’s friend realized that if anyone was to crack this nut, it was Bengt.

Bengt had always been a problem-solver and innovator. That was, and is, his main chaacteristics. That, and a healthy dose of stubbornness. And when the first couple of dumbed down computer languages that were available for the Vic-20 weren’t up to the task, he swiftly learned Assembly machine code and wrote a program to computer-control the lift. It worked beautifully.

What if the lift already knows what floor you’re going to, based on previous rides? What if it even can anticipate your actions before you yourself can?

[Bengt Wirgart]

Let’s start a lift solution company!

Bengt held out as a service technician at the Vic 20 company for a few years. At times he helped his old friend with new computer controlled lift systems, each time the systems and solutions became more and more sophisticated. Finally they both saw the potential and decided to go into the lift system business together and started Hisstema in 1986.

At the new company they primarily refashioned old mechanically controlled lifts by devising highly advanced computer controlled lift solutions. Business boomed. Until it didn’t. A falling out with his old friend over how the company should grow made for a split and in 1989, Digisign was started.

Wrote a program to computer-control

02

Bengt swiftly learned Assembler machine code and wrote a program to computer-control the lift. It worked beautifully.

Digisign takes off.

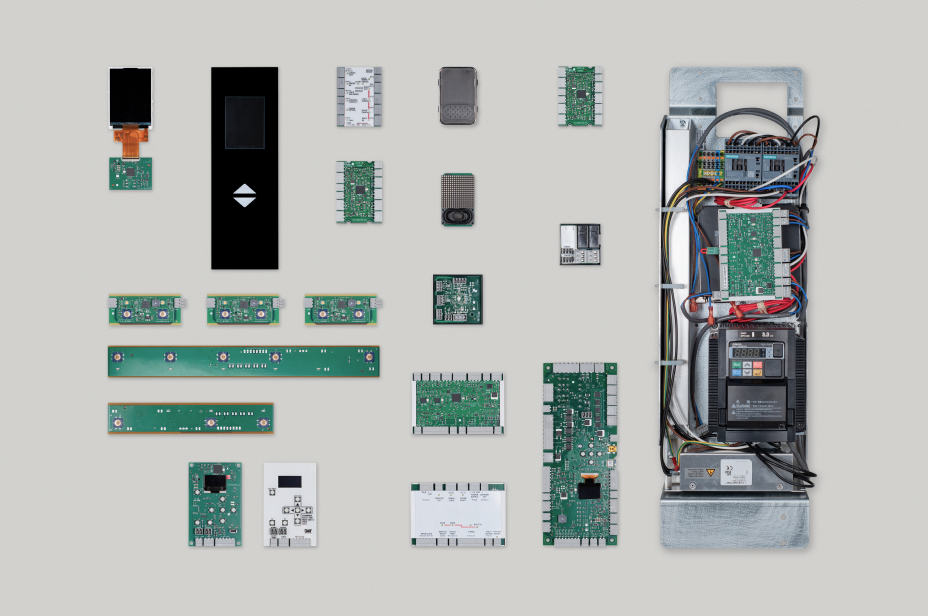

Digisign was founded on the idea of creating unique digital design (Digisign) lift products and services – control computers and control systems. The vision was to create customized products that was flexible enough to fit many lift systems, but still easy to install, own and service. They soon realized that to achieve that high ambition they needed full control over every part of the manufacturing process – from initial concepts and ideas to manufacturing and aftermarket services.

Keeping everything inhouse.

The business grew steadily during the 1990s and the company have continually added new products and services each year. Lift buttons and panels, key switches, indicators, emergency lighting all became part of the overall offer. And everything was conceptualized and manufactured inhouse by small dedicated teams that loved everything related to lifts.

Growing with the building boom.

Since the 2000s, Digisign has grown alongside the building boom. In 2005, Digisign took full advantage of the new strict and complex regulations and directives from the EU regarding lifts, accessibility and heavy machinery. Both new and old buildings had to comply with the regulations and Digisign had the products and services to fulfil the need.

As we reach today, the company is striving with some 45 employees in Västberga outside of Stockholm. It’s a bigger company than it used to be, but still remarkably agile – still innovating, still dedicated to the one thing their one passion, lifts.

Bengt swiftly learned Assembly machine code and wrote a program to computer-control the lift. It worked beautifully.

Wrote a program to computer-control

Only way forward is up.

What once started as one man’s vision is now a powerful and autonomous organization sharing that original and singular passion for lifts. What the future will hold we still don’t know. But what we do know is that the digitalization of lift systems are about reach another critical threshold with the emergence of machine learning and AI. And if you happen to possess an infatuation for lifts, you start asking yourself questions.

What if the lift already knows what floor you’re going to, based on previous rides? What if it even can anticipate your actions before you yourself can? What if it knows when it’s about to blow a fuse, stop functioning, and automatically calls in the repair team?

Well, these are questions most people never think very much about, but rest assured, the teams at Digisign are.

What we do

We work with a self-developed modular system that gives us the opportunity to quickly develop new solutions based on our customers’ specific needs and conditions.

That's how it worksOur process

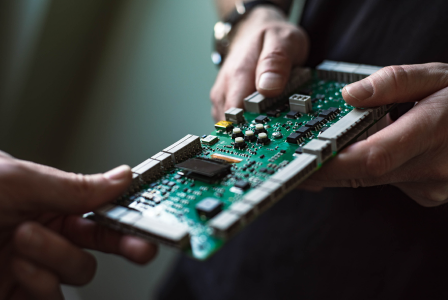

At Liftlogic, we work in close collaboration with our customers throughout the entire development process to create customized and unique control systems together.

Our process